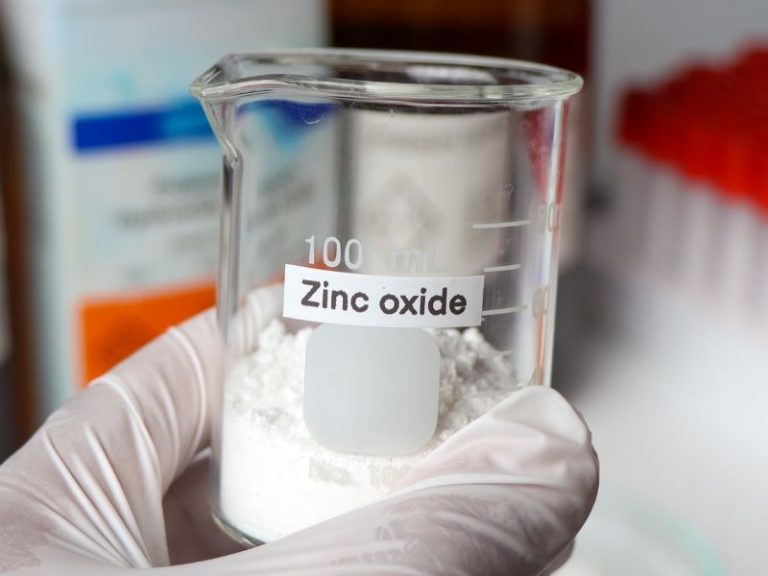

Pure Zinc oxide powder (ZnO) is one of those materials that quietly plays a big role in many industries. At first glance, it appears to be a fine white powder with the chemical formula ZnO. Although almost insoluble in water, its distinct physical and chemical traits come from its structure and purity. These features are what make it so valuable in fields like electronics, cosmetics, and medicine.

Composition of Pure Zinc Oxide Powder

At its core, pure zinc oxide is composed of zinc (Zn) and oxygen (O) in a simple 1:1 ratio, resulting in a molecular weight of approximately 81.37 g/mol. It is an amphoteric oxide, which means it can react with both acids and bases. For example, it dissolves in hydrochloric acid to form zinc chloride and in alkalis to form zincates.

In nature, zinc oxide shows up as the rare mineral zincite, often tinted yellow or red due to impurities such as manganese. However, the powder used in industries is produced synthetically, usually with purity levels higher than 99%. Its crystalline form typically adopts a hexagonal wurtzite structure, which is the most stable under normal conditions and gives it many of its unique properties.

Physical and Chemical Properties

Zinc oxide is known for being thermochromic. When heated, it shifts from white to yellow because of the lack of oxygen, then turns white again once cooled. It has a melting point of about 1,975°C and a boiling point of around 2,360°C. Dense and practically insoluble in water, ZnO does dissolve in acids, alkalis, and certain organic materials.

One of its standout features is its semiconducting nature. With a wide bandgap of around 3.37 eV, high electron mobility, and strong luminescence, it is ideal for applications like UV protection, electronic displays, and sensors. It also bonds easily with fatty acids to form zinc carboxylates, which are common in lubricants and cosmetic products.

Methods of Synthesis

Zinc oxide can be produced using both metallurgical and chemical routes. Popular chemical techniques include sol-gel, hydrothermal, solvothermal, emulsion, and aerosol pyrolysis methods. Each one affects the final particle size, shape, and purity.

Hydrothermal synthesis, for example, involves controlled precipitation of zinc salts under specific conditions, allowing fine-tuning of particle size by adjusting temperature, pH, and time. On the other hand, aerosol pyrolysis creates extremely pure nanoparticles, usually between 20–30 nm in size. Often, surface modification with organic or inorganic compounds is applied to tailor ZnO’s performance for specialized uses.

Functions and Applications

The real value of zinc oxide lies in its versatility:

- UV Protection.

- Antibacterial and Antifungal.

- Electronics.

- Photocatalyst and preservative.

- Dentistry.

From its chemical makeup and synthesis methods to its broad range of applications, pure zinc oxide powder continues to prove why it is an important material in modern science and technology.